LSP partners WEISS and Vötsch for all your needs in Environmental Test Chambers. WEISS and Vötsch are one of the world’s leading manufacturer for environmental simulation, heat technology, air conditioning technology and solutions for pharmaceutical technology.

Environmental Test Chambers

Environmental Test Chambers enable you to test the effects of temperature and humidity on the properties, function and lifespan of your products. Reproducible, certified and under accelerated conditions.

Available in a variety of test volume, temperature change rate and humidity functions.

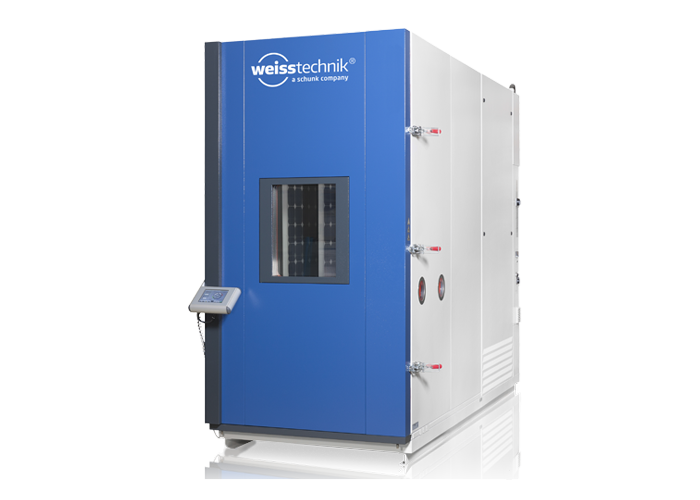

Walk-In Climatic Test Chambers

Environmental Test Walk-In Chambers can be configured quickly and easily. The wide range of options enables us to meet your individual needs resulting in a perfectly coordinated complete solutions, that will meet even the highest standards of your industry.

Benchtop Temperature Test Chambers

Benchtop Temperature Test Chambers allow you to conduct ideal temperature tests for smaller test specimens in the areas of research, development and quality control. A temperature range of -70°C to +180°C offers the ideal conditions to test resistance of test specimens against extreme temperatures.

Laboratory Test Chambers

PCBs, blister packs or lipstick – tests to stabilise and optimise the quality of products indispensable in research and laboratories. The Laboratory Test Chambers were designed for this purpose in particular to allow reproducible temperature and climatic tests directly at the workplace. A high temperature range from -70°C to +180°C and humidity range between 10% RH to 95% RH available for configuration.

EMC Test Chambers

The EMC Test Chamber enables you to examine the effect of temperature on your samples and benefit from the optimal shielding effectiveness during the EMC tests. The test space is designed to realize a shielding function of the internal container, i.e. the ability to reduce electromagnetic fields and surface currents.

Thermal Shock Test Chamber

Environmental conditions have a great effect on the functionality and reliability of electronic components, devices, and systems. In order to discover latent weaknesses in the shortest possible time, a typical temperature test is often insufficient; test specimens must be subjected to multiple, abrupt temperature changes. With our temperature shock test cabinet, extremely rapid temperature changes in the range from -80 °C to +220 °C can be implemented. This allows you to reduce the incidence of early failures and increase the reliability of your products. Reproducible, certified, and in time lapse.

Vibration Testing Chambers

In particular, components from the automotive and aerospace industries are subject to intense vibrational forces during operation, whereby these can experience rapid temperature changes in different climates.

The ShakeEvent series of the weisstechnik® and vötschtechnik® brands will enable you to simulate such dynamic processes as well as the associated combined mechanical and thermal/climatic stresses that act on components and devices. You can therefore investigate the stress limits in order to ensure safe driving or flying operations.

Vacuum Test Chambers

Planes, satellites, space shuttles and helicopters – aircraft must resist extreme temperature fluctuations and humidities in vacuums. It is therefore important to test these highly stressed components for quality and durability before use.

With our vacuum test chambers, you can simulate extreme environmental conditions. Combined temperature and vacuum tests ≥ 400 mbar and temperature ranges from -70 °C to +180 °C can be reproduced. The measurement results provide you with reliable data to optimise the development and production processes.

You need more? Our SkyEvent climate test chambers cover even more extreme test conditions.

Altitude Simulation Chambers

Aircraft are subject to extreme pressure and climatic conditions during flights. These parameters have a significant influence on the functioning of individual components and they must be monitored and measured for safety reasons. weisstechnik® test cabinets allow for the testing of aerospace components in an environment with controlled pressure, temperature and humidity parameters. An altitude of 100,000 feet can be simulated. If desired, combined Cat B icing tests in accordance with the standards RTCA DO-160 and MIL-STD-810 can be carried out.

Test System for Lithium Ion Energy Storage Systems

Alternative drive systems are a central component of the automotive future. In comparison to other mobile storage systems, lithium ion batteries and fuel cell technology have become established. Increasingly larger applications require storage systems that both have a very high energy content and supply a high level of power.

An energy storage system must be as safe as possible. External loads, e.g., caused by high or low temperatures, fast temperature changes, humidity, mechanical loads or corrosive influences, must not lead to failure or unintended reactions.

During the temperature tests, overload conditions or malfunctions may occur. They could ultimately result in batteries being destroyed. With the ever increasing size of storage systems, the impact of a malfunction becomes larger and the potential danger when testing lithium batteries increases. Therefore, when doing such tests safety in the laboratory, above all personal safety, has the highest priority.

We work together with you to exactly tailor our li-lo test systems of the weisstechnik® and vötschtechnik® brands to your test conditions.

Temperature Vacuum Test Chamber

Testing aerospace equipment before the first flight into space is a requirement in order to be able to predict the behaviour of these valuable components. They are tested by simulating space conditions.

The weisstechnik® temperature vacuum cabinets accurately reproduce space conditions and make it possible to conduct such a test in a completely controlled environment. Our high-performance pump systems can reach a vacuum of up to 10-7 mbar. Liquid nitrogen, which circulates in the temperature vacuum cabinet produces temperatures from -185 °C to +165 °C. Features, such as infrared radiation or a spacial temperature gradient, can be simulated according to the customer’s requirements.

PV Modules Test Chambers

Photovoltaic systems are used in various different areas worldwide. To produce energy, PV modules are installed on the ground, on industrial buildings, in private households, charging stations, vehicles, planes, etc. This makes it all the more important that these modules work perfectly while resisting all climatic conditions.

The test chambers with an extra wide or high interior test space allow you to test for suitability and service life with temperature changes, moisture/frost or moisture/heat constellations according to IEC 61713, IEC 61215 and IEC 61464. Temperature ranges from -70 °C to +180 °C as well as high processing and construction quality are crucial for reliable measurement results.

Corrosion Alternating Tests Chamber

High air humidity, salty air, sea water or road salt, many small and large items of day-to-day life are subject to corrosive influences. Corrosion does not only eat away at base metals, but also highly alloyed, tempered materials, plastics and painted surfaces. Therefore, resistance to corrosions is an important mark of quality and safety for many products.

You can use the SaltEvent SC-KWT corrosion change test devices from weisstechnik® to investigate the impact of salt spray, condensation water and normal climate – individually or combined, and automatically. Thanks to the sophisticated construction and high quality workmanship, the test devices have excellent temperature consistency and in this way, they guarantee correct and reliable results.

Test Chambers for Ozone Resistance Tests, Type OZ

Due to its oxidising effect, the ozone, even in typical environment concentrations, may lead to the premature ageing of and damage to materials and components. Plastics and polymers are particularly at risk.

Using the WT/WK-OZ test cabinets of the weisstechnik® and vötschtechnik® brands, you can find out the ozone resistance of your products. For this purpose, the product is subjected to an ozone concentration of 25 to 200 pphm at +40 °C and 55 % relative humidity. The test cabinet is suitable to perform both static and dynamic (in combination with expansion) endurance tests.

Precision Climate Test Chambers for particularly stable and homogenous test conditions

Some applications, e.g. the calibration and adjustment of sensors, require particularly stable and homogeneous climate conditions. weisstechnik® has developed specialised precision climate test cabinets for these applications on the basis of the ClimeEvent series.

Technology for maximum precision

The precision climate test cabinets offer all of the benefits of the tried and tested ClimeEvent series, and use a variety of technical measures to achieve the required level of precision. The cabinets also have an optimised air supply, ensuring a particularly equal distribution of air.

Dust Test Chamber

With dust test chambers of weisstechnik and vötschtechnik you can carry out protection class tests in accordance with DIN EN 60529 (VDE 0470-1) IP5X and IP6X. Standard chambers are available in sizes of approx. 1000 l and approx. 2000 l.

In addition, we offer customized sizes on request in order to meet specific requirements.

Optional equipment is also available so that further standards can be complied with, including:

- ISO 20653

- SAE J 575

- MIL STD 810

- IEC 68068

Please note that the test chamber can only meet the applicable section of the standard.

Spray and splash Water Test Chamber

The weisstechnik and vötschtechnik splash water test chambers can be used to perform IPX3 and IPX4 protection class tests according to DIN EN 60529 (VDE 0470-1) IPX3. The chambers are available with swivel tube radii of 200 mm and 600 mm. The maximum possible swivel tube radii are 400 mm and 800 mm.

Optional equipment is also available so that further standards and protection classes can be complied with, including:

- ISO 20653, IPX1K to IPX6K, IPX9K

- DIN EN 60529, IPX1 to IPX6, IPX9

- SAE J 575

- JIS D 0203

- MIL STD 810

- IEC 68068

Please note that the test chamber can only meet the applicable section of the standard.